Web Log

There is No Such Thing as Workflow Medical professionals always talk about workflow and that is a big problem

12/17/2025 9:48 PM

There is No Such Thing as Workflow

Medical professionals always talk about workflow and that is a big problem

Introduction

Normally, we talk about health care and health insurance in this space and today is no different. Today we are going to discuss workflow thinking, why it is bad and how it is holding the entire medical profession back and impeding progress and improvements in the industry.

Every employee of every hospital and practice in the United States will talk about workflow. When they say workflow they mean the steps necessary to move a patient through the process. On the surface, that sounds great, but we will prove that this thinking is literally killing people and losing at least hundreds of billions if not trillions of dollars annually.

The Situation

A patient goes to the practice or hospital. They get processed for admission, they get asked a bunch of questions, they have to write a bunch of answers on paper, then get shunted to the waiting room where they wait. They get called and go to a treatment room where they wait. They get seen by a harried practitioner for 7 minutes and then some treatment is prescribed and they are sent home. Everyone in this process is overworked, underpaid and frazzled to the bone. Everyone has his or her little station and that is where they sit until the patient gets to the treatment room, where, for the first time, an employee, the practitioner, comes to them. This is workflow. We are all familiar with it and can’t think of how else it would be done. However, if Ford built F-150s this way, they’d be bankrupt in a month.

At the hospital level it is even worse. A gaggle of nurses sit at a station typing on some silly EMR/EHR. Doctors see patients sporadically at best and don’t communicate with each other, the patient or the nursing staff. I have written about medicine, healthcare and health insurance now for years, but recently my mother was diagnosed with a tumor on her thalamus. I saw all of this first hand at the facility where she was taken. She had three or four doctors, a neurosurgeon, the aforementioned nursing staff in shifts, a technical staff to take care of the room, a diet staff to keep her fed, an occupational therapy staff to rehabilitate her and just monkey motion in general.

I suspect that about the vast majority of the effort expended on her behalf was wasted. Had there been adequate communication between the cast of dozens, we could have had her in and out in one day instead of over a week.

The Logical Conclusion

Workflow thinking, assigning staff to rooms, no valid communication between the doctors, and people just running around being important, or doing whatever they think is best, is the problem. I can only speak from

my personal experience, but that experience tells me that somewhere around 80% of the effort expended was wasted. If this continues, medical care will collapse under its own weight and we will either be left with nothing, or something so eye-wateringly expensive as to be functionally the same as being left with nothing.

The Short Answer

Run a hospital like a manufacturing plant. Instead of running from fire to fire as if short staffed, coordinate care and integrate everyone into one seamless, non-linear production line. Wait, what? The production line sounds very linear. Let’s take a look at the assembly line Henry Ford adopted and see how it really works

While it appears that the parts to bolt on a car just appear, that is far from the truth. The car moving down the assembly line is analogous to the patient, except that the workers move instead of the patient. The problem is what happens before we get to the assembly line. Ore must be processed into steel and aluminum, glass produced and rubber fabricated. Pistons, crankshafts connecting rods and all the parts of the car moving down the production line must be completed and tested before the production of the car even starts. Instead of linear, workflow thinking, a nurse for four rooms, a dietician for several rooms, and on and on, we need a queued process where the most urgent use of time is done first, and dependencies like pistons and crankshafts or an MRI have priority.

The Slightly Longer Answer

Instead of steps in a process we have to think about dependencies. We have to have all the care necessary ready and waiting on the patient to arrive, like fenders on an F-150. I propose we assign patients to queues of tasks. Then we can assign any of several employee resources to work any of several queues. In the case of my mother, the surgeon knew at 7:00 AM the morning following the admission that the tumor was inoperable. This news was communicated to nobody but me. So we sat in the hospital, wasting resources, seeing various doctors and specialists and getting wheeled around for a dozen tests that just didn’t matter. Finally, they did an MRI, the surgeon read it and announced the verdict to the world. Seven days later. The day after that, I brought her home. Had we had queues we could have added her to the MRI queue, seen that she had a bladder control module, called the manufacturer that day and had

the whole thing resolved in 12 hours.

These queues, arranged by employee, can be implemented on a phone or tablet device. These are lightweight, cheap and easy to use. This screen will show what the best use of time is right now and allow the hospital or practice to calculate efficiencies and costs for each employee. A phone would also serve as an instant communication device among staff.

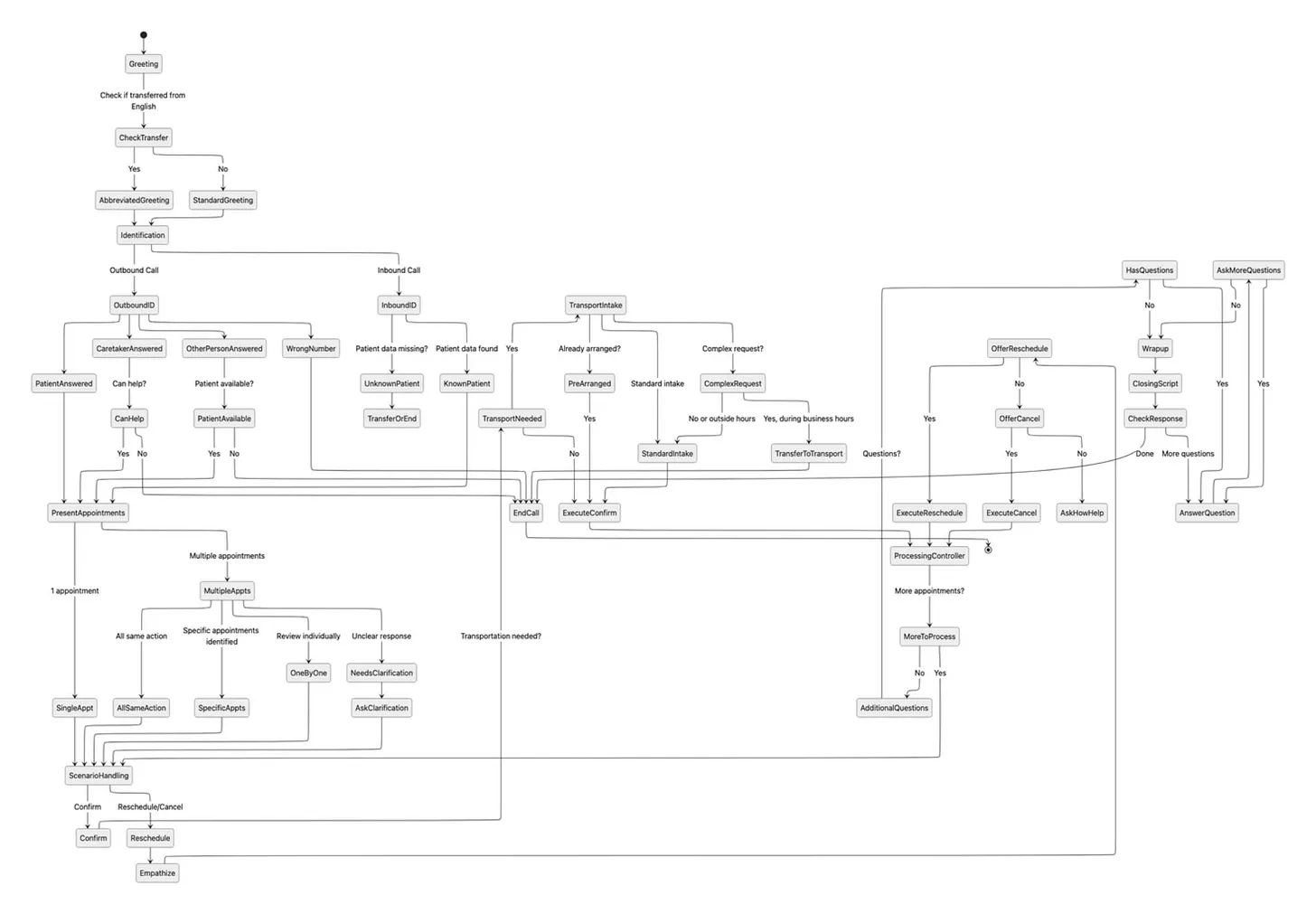

Rik Rynard posted this image on LinkedIn depicting the ‘workflow’ necessary to set an appointment:

While we think this is a little bit overly complicated, this could be solved with a couple of queues, like “New Patient,” “Existing Patient,” “Difficult Questions”, “Arrange Transportation,” etc. With just a couple of people working all of these queues, and with the queues aggregated by employee and ordered by urgency, you can replace this entire ‘workflow’ with one or two people, and have those people cross trained to do several other things. This is efficient.

Rik, we love you, but you’re not a programmer and this is overly complicated and people will fall through the cracks. With a series of queues, nobody will ‘get lost in the system’ and every patient must have some kind of resolution, even if it is getting assigned to another queue, or be marked as complete.

Let’s talk a little more about manufacturing. Each step in a manufacturing process is a queue as above. We have to have all the parts for a step before it is executed. We have to have all the pistons, the block, the crankshaft, the camshafts, ad nauseum before we can complete the engine building step. If the piston guy calls in sick, we need the crankshaft guy or whomever has excess capacity to step in and help out. If the MRI is backed up, we need to increase capacity or cross train to get extra capacity in times of heavy usage.

In addition to the queues we need communication. Every step in a process has to have some kind of resolution. Usually, successfully completed, or assigned to the “Arrange Transportation” queue. Or “CT Scan shows inoperable tumor on thalamus, confirmed with MRI.” This is literally coordination of care. Coordination of care is one of two tenets of Value based care, along with “Deliver Value.” With this kind of system in place, and only with this kind of system in place, can we get to value based care and we turn an eight day hospital stay into a 12 hour hospital stay. Saving instead of wasting those resources is one large way to deliver value based care.

Our basic motivation is to have these queues identify the best use of time between and among each, in a competition for resources, and assign those most critical tasks to individuals in a “worst needs get handled first" kind of way.

Eli Goldratt has a treatise on this subject in his book “The Theory of Constraints” that we have applied here.

Conclusions

The only thing we think about is Sentia Health is to streamline, automate and save healthcare by delivering value. We have shown a way to cut large swaths of work out of the clinical process, utilize medical professional’s time more efficiently, practice’s and hospital’s resources more efficiently and bring the cost down for everyone.

This queueing system is part of our larger Hospital/Practice Management System HPM. This system is designed and in development. It integrates fully with our Electronic Medical Records Management System (EMR) flawlessly and seamlessly with zero copy and paste or retyping. Remember, that coverage is also integrated with the EMR, so that as patient care is documented payment is transferred in real time, automating the entirety of the health insurance industry. You can read about that here.

The HPM is also a fully fledged Enterprise Resource Management System (ERP). That means we can run a profit and loss statement (P&L) on any resource in the practice or hospital; employee, room, equipment, consumables, department, or the entire enterprise in seconds with one click. That helps us find cash leaks and inefficiencies instead of hiring and paying for an army of accountants with spreadsheets weeks at a time to find them.

Finally, integrated into the EMR is a Health and Wellness system that we use to manage chronic disease. As care is documented, the system automatically assigns patient education reading to the patient. There are articles about any kind of chronic disease, particularly behavior-based, avoidable disease, and also the most frequently occurring care such as post surgery direction for an appendectomy. The best part is that as patients read the education and follow the instructions and actually get better, as evidenced by lab results, we can offer them substantial discounts on health insurance. That shifts the burden of not living a healthy lifestyle to the people who aren’t living it.

We already have the best doctors and the best equipment; we just need to implement the above detailed framework to give them all the tools necessary for success.

We have the EMR system in prototype now, fully functioning. We have the HPM system in development and will move to production soon.

Contact us here or on our site and we will be happy to provide a demonstration of the fully functional EMR prototype.

If you liked what you read, please like and subscribe, click on the notification icon, subscribe to our newsletter, and follow us on all our social media and blog sites.

We have built a comprehensive health information system to keep the patient healthy and on the right track with the ability to incentivize healthy living. This system includes the automation of the health insurance industry completely. We have designed and are currently building the ERP style PM system. Implementing this system should be fairly simple and will completely revolutionize the way healthcare is delivered and paid for, saving countless lives and trillions of dollars.

We have shown a way to use this system to make the best healthcare system in the world also the most efficacious and the most affordable.

If you liked what you read contact us here, on our site, SentiaHealth.com, our parent company SentiaSystems.com, or send us an email to info@sentiasystems.com or info@sentiahealth.com

| Date Written | Comment By | Comment |

|---|